Is SaaS Dead?

August 24, 2025

Our Most Valuable Portfolio Company Yet

September 5, 2025The Making of the Atomic Bomb — the Manhattan Project —, by Richard Rhodes, is the epic account of humanity’s greatest engineering project, a feat that dwarfs the Apollo moon landing.

The book covers it all: the rise of nuclear physics, the scientists’ lives, Europe’s turmoil and emigration to the US, WWII’s pivotal events and figures, the bomb’s design and testing, the moral calculus of its use, etc. Here, though, I focus on one aspect — producing fissile fuel, the project’s greatest and most capital- and resource-intensive achievement, undertaken on a scale unprecedented in human history.

Nuclear scientists understood the bomb’s fissile fuel could come from uranium enrichment or plutonium production, but since no one knew which would succeed, both efforts were pursued in parallel.

Uranium: The Isotope Separation Challenge

Natural uranium consists almost entirely of U-238, which cannot sustain a chain reaction. Only about 0.7% is U-235, the fissile isotope needed for a bomb. The challenge was immense: separating U-235 from U-238 was like trying to distinguish twins, as the isotopes are chemically identical and differ only slightly in mass.

Two parallel paths were pursued.

One was electromagnetic separation, where giant magnets bent beams of ionized uranium so that the lighter U-235 atoms diverged slightly from U-238 (California University Cyclotrons, Calutrons). This method was proven early and provided the first usable stockpile of U-235 for Little Boy, but it was enormously inefficient — consuming vast amounts of electricity, demanding hundreds of operators, and yielding only small quantities

The other, gaseous diffusion, forced uranium hexafluoride gas through a sequence of porous membranes, with U-235 slipping through fractionally faster. Although plagued by material shortages and sealing problems that slowed progress, once perfected this method proved vastly more scalable and efficient, ultimately overtaking electromagnetic separation.

Both U-235 production facilities were built in Oak Ridge, Tennessee.

The Calutron complex employed more than 22,000 workers and housed several massive racetracks of electromagnetic separators. Each of the two main buildings was about 120 m long, containing 1,152 Calutrons in total. The facility consumed 200 megawatts of electricity — about 10% of the entire Tennessee Valley Authority’s output at the time — and ultimately produced only about 50 kg of U-235.

The gaseous diffusion plant was the largest building in the world at the time — a massive U-shaped structure covering about 150,000 m². Each leg of the “U” stretched nearly 800 m. The facility required thousands of tons of nickel and specially engineered porous barriers for the diffusion membranes. It consumed around 250 megawatts of electricity continuously — more than many large cities of the era — and involved tens of thousands of workers to construct, plus several thousand operators and engineers to keep it running once operational.

Plutonium: The New Element

Scientists discovered that uranium reactors could “breed” a new element — plutonium-239, itself fissile — when uranium-238 was bombarded with neutrons. But plutonium was chemically bound with uranium inside the irradiated fuel, and it was intensely radioactive, creating extraction and handling challenges on a scale never seen before.

To produce it, the Manhattan Project built vast graphite-moderated, water-cooled reactors along the Columbia River at Hanford, Washington. Each of the eight reactors was an enormous graphite block about 11 m tall, 11 m wide, and 8.5 m deep, penetrated by 2,004 aluminum tubes loaded with uranium fuel slugs. Cooling required a torrent of river water — about 285,000 liters per minute — pumped from the Columbia and returned after treatment.

Once irradiated, the uranium fuel rods were dissolved in nitric acid and sent through massive chemical separation facilities known as the “canyons.” The first two plants were each about 245 m long, 20 m wide, and 24 m high, roughly the size of an aircraft carrier. Inside, entirely new chemical engineering processes were developed to separate plutonium from uranium and fission products. To protect workers, the canyons employed remote-handling equipment and were shielded by reinforced concrete walls up to 2 m thick.

The Hanford complex eventually employed tens of thousands of workers during construction and thousands more in operations, producing the plutonium for the Trinity test and the Fat Man bomb dropped on Nagasaki.

Conclusion

You see, I told you it couldn’t be done without turning the whole country into a factory. You have done just that — Niels Bohr (to Edward Teller, upon learning of the scale of the Manhattan Project in 1944)

It once took tremendous capital (but taxpayer money) and brains to scale up fissile fuel production.

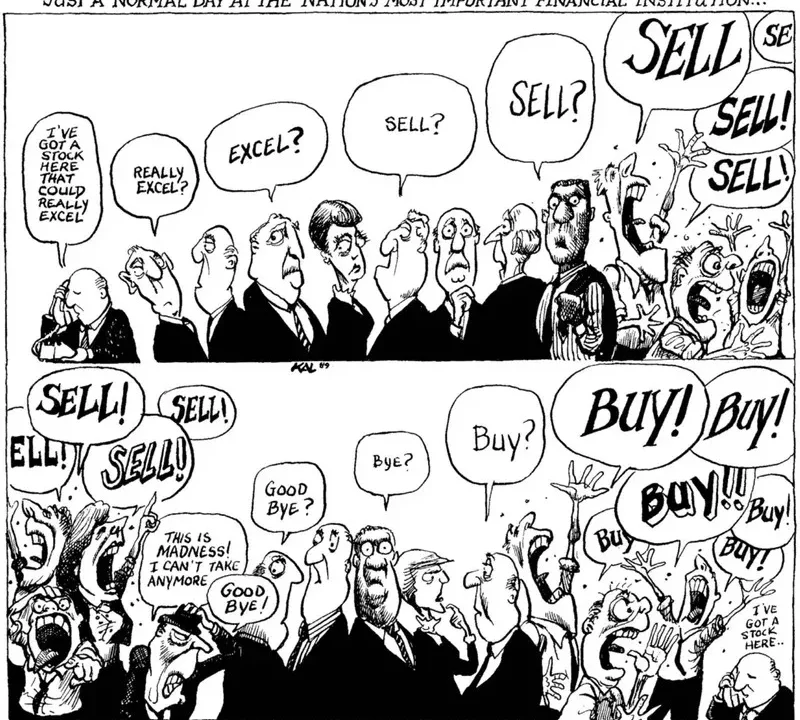

Now, the most extraordinary techno-capital acceleration (scaling at over an order of magnitude annually) since the Manhattan Project has begun — trillions are flowing into GPUs, datacenters, power, and brilliance in the drive toward AGI.

The Intelligence Explosion is scaling up fast.